Three-dimensional XL targets are durable, low maintenance, and non-electronic

HawkEye® XL HD Wheel Alignment Machine

Fast and highly-capable heavy-duty tyre alignment machine

High-definition cameras are accurate, precise, and offer extra-long-range sight

Capture all measurements in a single rolling compensation

See live wheel alignment reading from three axles at once

Perform wheel alignments on any surface, in any bay

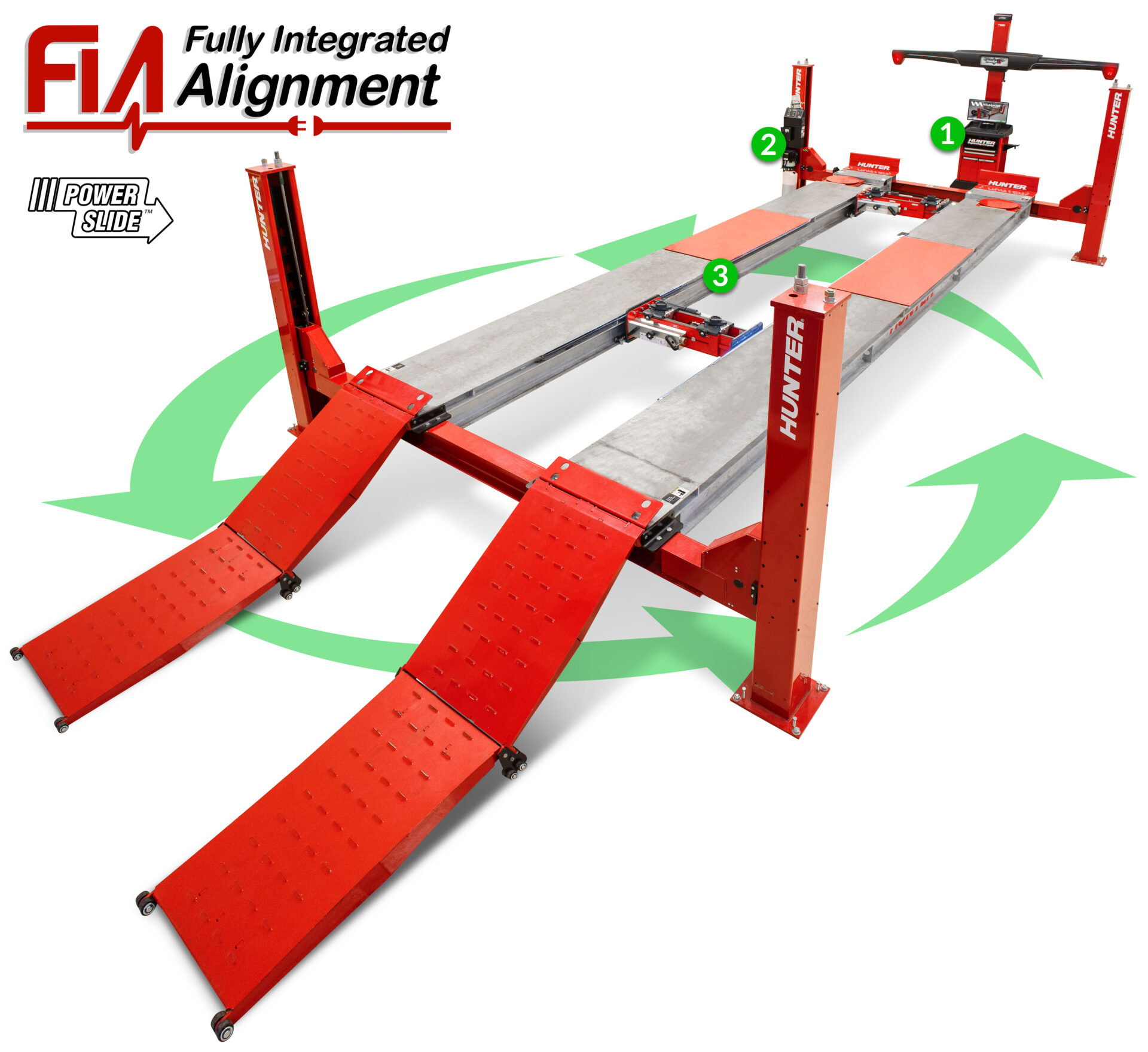

Fully Integrated Alignment rack integration streamlines processes

HunterNet® 2 online portal tracks revenue, results, ROI and more

Big or small, align them all with HawkEye® XL

Hunter Engineering’s new Hawkeye® XL aligner handles everything from Class 8 trucks down to passenger vehicles.

New HawkEye® XL commercial aligner helps Prime Inc maintain its “nonstop” pace

“For us it’s more income. We bring in more money, more revenue, using a more efficient machine.”

HawkEye® XL Alignment System Beginner's Operation Guide

Hunter’s new HawkEye® XL aligner is designed for maximum speed, durability and ease of use for heavy-duty, medium-duty and light-duty vehicles, providing accurate measurements in four minutes or less.

Supersize your alignment capabilities with the Hawkeye® XL

Hunter Engineering’s new Hawkeye® XL aligner handles Class 8 trucks down to passenger vehicles.

Features

Hunter's industry-standard vision technology built for commercial vehicles

XL Targets

Hunter’s patented 3D targets offer extreme durability, low maintenance, and no electronics at the wheel.

High-definition cameras

Extra-long range, high-resolution cameras precisely monitor each wheel in a 3D space to provide pinpoint accurate measurements.

Multi-Axle Readings

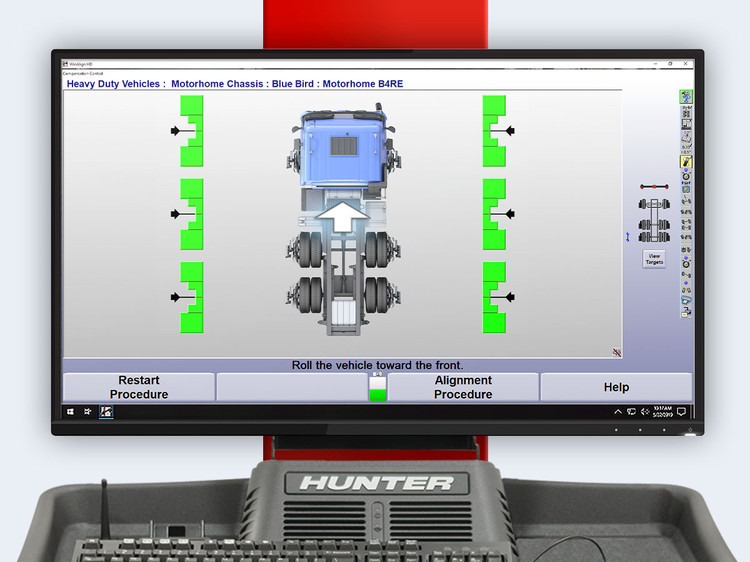

See live wheel alignment readings from three axles at one time with guided procedures.

Alignments in any bay

Move the wheel aligner for use in any bay, on the floor or a lift with adjustable camera beam.

Trailer alignment

Long range cameras easily see targets on 53 foot trailers. Align using optional kingpin adaptor.

Truck Pusher

Effortlessly move vehicle for rolling comp with rechargeable battery-powered pusher.

Return on investment

Calculate your payback and HawkEye® XL profits

Did you know?

Approximately 70% of trucks are out of alignment. Proper tyre alignment machine can save fuel and prevent premature tyre wear. Alignment can also reduce driver fatigue, which in turn improves road safety.

Alignment lift rack integration

Streamline the process with Fully Integrated Alignment (FIA)

1 trip

To the aligner console

0 jacking axles

Required

81 steps

Total in the process

4 minutes

To get alignment readings

- WinAlign® console Communicates directly with lift to automatically operate turnplates and slip plates.

- Heavy-Duty Four-Post lift console Raising the vehicle triggers the sensors to look for wheel targets.

- PowerSlide® system Slip plates and turnplates automatically lock and unlock at the appropriate times.

Requires FIA-capable Hunter lift or turnplates

Adaptability

Ready for your entire fleet or whatever comes through your door

Align a wide range of commercial vehicles from semi truck, trailers, big rigs, buses, box trucks, and even passenger vehicles.

Truck and Bus alignments

Trailer alignments

Medium-duty truck alignment

Light-duty vehicle alignment

Equip your shop to be ready for any vehicle.

Unmatched software

Patented technology maximises productivity in your alignment bay

Guided procedures

Vehicle specific procedures guide the operator with step-by-step instructions.

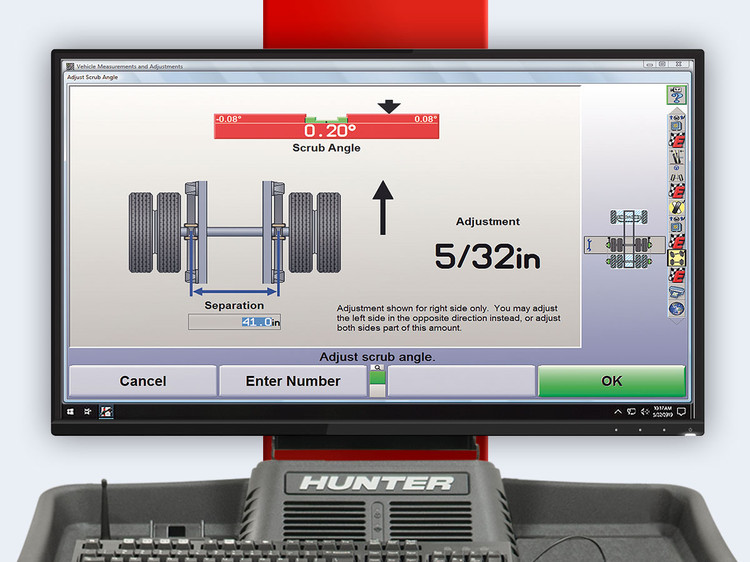

Patented power tools

Procedures designed so you can complete the work accurately the first time, every time.

Light-duty vehicles

Additional features included for servicing light-duty vehicles.

See three axles live with all measurements at once. Reduce setup time through minimal target movement.

Perform every tyre alignment with a streamlined procedure. ExpressAlign® analyzes each job and presents the optimal action sequence with the minimum steps required.

Select from over 60 procedures to perform the fastest, easiest, step-by-step alignment process on virtually any vehicle.

Ensure a straight steering wheel every time without repeated adjustments or using a steering wheel holder. Works with all vehicles on the road today, from cars to Freightliners.

Cut adjustment times in half for rear axle corrections. Graphics let you get it right on the first try.

Patented

Calculate the proper bushing size and position adjustment without wasting time with a zero bushing. Eases the process of servicing Ford F-150-450’s.

Patented

Strengthen technician competency and extend profit opportunities with helpful adjustment videos.

Lease to own over 60 months

with repayments

Your business can lease to own this Hunter Hawkeye XL HD Aligner from approx. $450.00 per week excluding GST on a 60 month term. Included is our 36 month comprehensive service agreement, which covers all parts and labour & includes 6 monthly preventative maintenance calls from our Hunter factory trained technicians.

from

$90.00

per day

Terms and conditions apply.

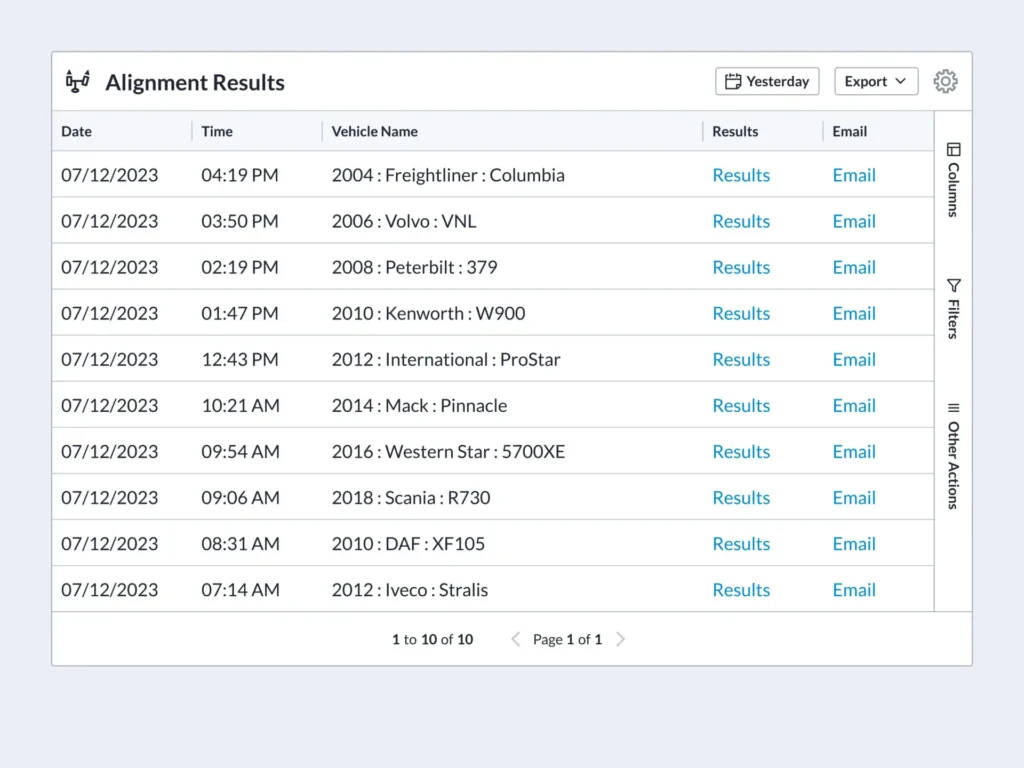

HunterNet® 2 Portal

Take control of your equipment, numbers, and profitability

Equipment intelligence tools help you manage your business and profits in real time

- Maximise your shop’s performance

- Monitor your equipment ROI

- Buy genuine Hunter consumables

- View real-time equipment activity

View previously serviced vehicles and recall printouts.

See your wheel alignment machine payback in real time.

Set goals and see how your business performs day-to-day.

Setup to receive daily Push Reports to keep your goals and performance in check.

Options and accessories

Equip your shop for efficient wheel alignments

Hunter’s Heavy-Duty Four-Post semi and truck lift features a 35,000-lb. lifting capacity, 300-in. alignment wheelbase capability, galvanized runways and turnplate pockets and slipplates for servicing standard vehicles. It can be equipped with optional Powerslide and FIA functions that connect it to the aligner to streamline your alignment process.

Turnplate options for floor or other racks

Surface-Mount

Utilize an existing pit

- Permanent installation

- Easily accomodates existing pits, no need for a rack

- Adjustable track width — half-ton to Class 8

- 22,000 lbs. (10,000 kg) per axle

- Built-in turnplate bridges for rolling compensation

Rack-Mount

Enhance your rack

- Compatible with Hunter HD alignment pit rack models

- Perform Quick Check®s and alignments more easily

- Adjustable track width — half-ton to Class 8

- 22,000 lbs. (10,000 kg) per axle

- Built-in bridges for rolling compensation

Flush-Mount

Great for new construction

- Level profile — reduces tripping hazards

- Provides clean installation and smooth approach

- Adjustable track width — half-ton to Class 8

- 22,000 lbs. (10,000 kg) per axle

- Built-in turnplate bridges for rolling compensation

Portable

Ultimate versatility

- Perfect for multiple bays or multiple steer axles (additional sets required)

- Mobile alignment service

- 22,000 lbs. (10,000 kg) per axle

Other accessories

- Rolling Storage Cart – Hang targets for quick access.

- Secondary Console Kit – Provide better visibility and control. Mounts to cart shown.

Mount to hub center of front rims. (set of 2)

Mounts to the kingpin for trailer alignments.

Maintain control while making adjustments.

Easily and accurately measure max steer.

Hunter Solutions

Get the most out of your tyre alignment system

Unlock profit potential with Quick Check® Commercial unmanned inspection

- Keep your equipment producing with a steady stream of high-margin wheel alignments

- Scan every truck, axle and tire that comes into your shop with no technician required

- Inspects for camber, total toe, scrub and tire wear in less than 30 seconds

Did you know?

Over the course of 5 million miles, a fleet with properly aligned wheels will save approximately $60,000 in fuel and 18 million miles of tyre life.

Advance your wheel alignment business

STANDARD

Self-Centering Adaptors

(Heavy Duty)

Fits 15-28″ rim diameter

OPTIONAL

ADASLink® with DAS 3000

(Light and Medium Duty)

Steering angle resets

Dynamic calibration

Static calibration

OPTIONAL

QuickGrip Adaptors

(Light Duty)

Two-axle vehicles

No metal-to-metal contact

How can we help?

"*" indicates required fields